In busy logistics hubs and warehouses, moving goods efficiently is a top priority. One tool that’s become increasingly important in this process is the telescopic belt conveyor. If you've ever seen a long conveyor sliding in and out of a truck like a giant mechanical arm, you've likely seen one in action. But what exactly is it, and how does it actually work?

Let’s break it down in a way that combines technical understanding with real-world application.

A Simple Definition

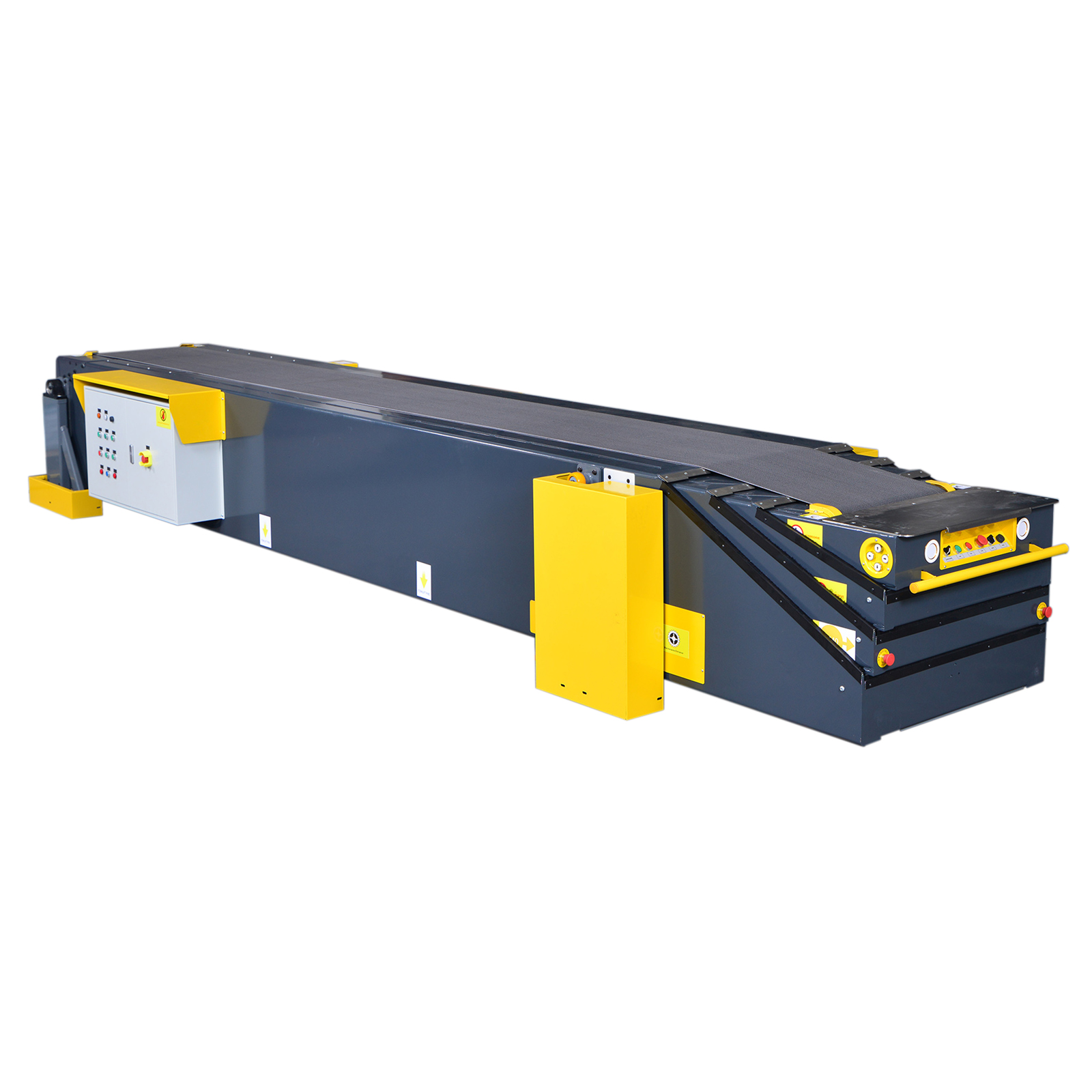

At its core, a 4 extension loading and unloading conveyor is a kind of conveyor system that can extend and retract, much like a telescope. This movement allows it to reach inside trucks or containers for easier loading and unloading. The design significantly reduces manual handling, improves safety, and speeds up operations.

In more technical terms, it's a multi-section conveyor where the nested sections slide out to extend the length. The belt moves continuously along these sections, even as the conveyor extends or contracts.

How Does It Work?

Now let’s get into the mechanics—without sounding like a textbook.

Imagine you’ve got a truck backed up to your dock. Instead of sending in workers to carry boxes one by one, you roll up the telescopic conveyor. At the press of a button (or using manual control in simpler models), the conveyor slides forward, reaching deep inside the truck.

The moving belt—usually made from durable rubber or PVC—carries boxes from the vehicle right into the warehouse or the other way around. Some models even let you adjust the height or tilt the conveyor to match different truck sizes or dock levels.

And when the job’s done? Just retract the conveyor back like a telescope and roll it away. Simple, right?

Key Features (from a Practical Viewpoint)

While tech specs matter, most warehouse managers care more about how it helps:

Adjustable length – So you can handle different truck sizes.

Height control – For aligning with containers or dock heights.

One-person operation – Reduces manpower costs.

Fast belt movement – Speeds up loading and unloading dramatically.

Safety mechanisms – Like emergency stop buttons and anti-slip belts.

Where Is It Used?

You’ll find mobile telescopic belt conveyors in a lot of places:

Logistics centers shipping thousands of parcels daily

Online retail fulfillment hubs (think e-commerce giants)

Courier and express parcel services

Airports, for baggage handling

Warehouses and storage facilities

Basically, if there are goods constantly coming in and going out, a telescopic conveyor makes the job smoother.

Why Are Telescopic Belt Conveyors So Popular?

Now, let’s get real. Time is money—and in logistics, wasted time equals wasted revenue. A conveyor that extends into a truck eliminates time-consuming, back-breaking labor. Not to mention, it cuts down the chance of workplace injuries.

From a formal point of view, telescopic conveyors are recognized as effective solutions for enhancing logistics productivity, operational safety, and space optimization.

And let’s not forget the long-term cost savings. Fewer injuries mean fewer insurance claims. Faster operations mean quicker turnaround. That’s good news for your bottom line.

Whether you’re running a small warehouse or managing a large distribution center, investing in a telescopic belt conveyor can seriously streamline your operations. It's not just a piece of equipment—it’s a way to modernize your entire loading process.

So next time you’re stuck waiting on slow, manual unloading? Just imagine how a telescopic conveyor could slide right in and change everything.